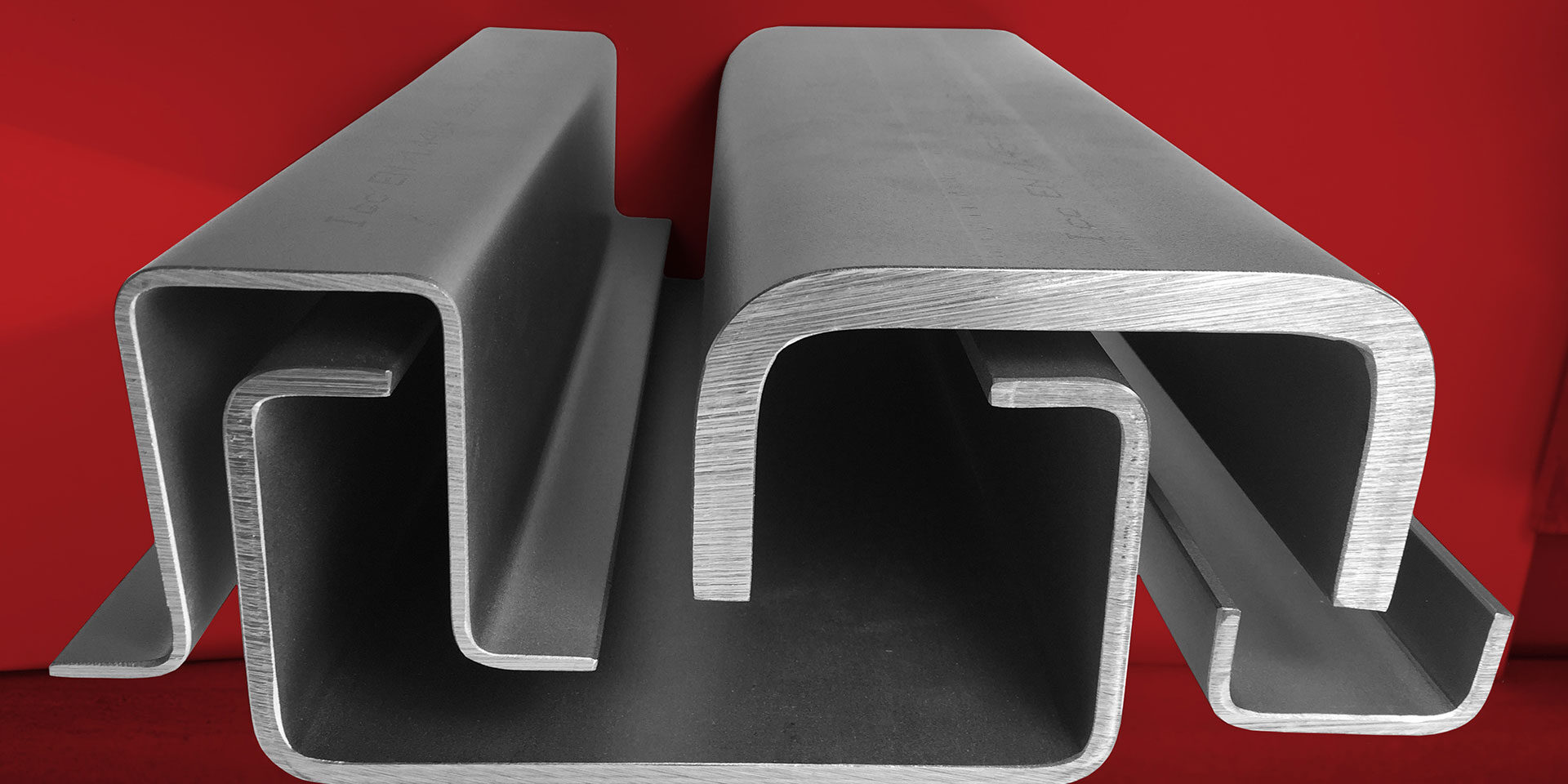

Made-to-design profiles (L-U-C-A): SIPI’s Tailor-Made Solution

Since 1992, SIPI has been a byword for excellence in stainless steel processing. Among its most valued offerings are the made-to-design profiles (L-U-C-A) – bespoke technical components designed to meet the growing demand for personalised industrial solutions.

Manufactured in stainless steel according to client specifications, these profiles are engineered to suit a wide range of industrial uses, including highly specialised and non-standard applications. The result is a perfect synergy between engineering rigour and manufacturing adaptability.

Technical specifications:

- Available thicknesses: from 3 mm to 15 mm;

- Available lengths: from 3,000 mm to 6,000 mm.

SIPI’s competitive edge lies in its ability to produce even small batches without compromising on quality or lead times. Thanks to two shears, three bending machines and a band saw, the company ensures a wide dimensional range (up to 500×100 mm), while maintaining high machinability standards.

Every production phase is subject to meticulous quality control: each profile is manually inspected to verify tolerance compliance and preserve the material’s original mechanical properties. This same attention to detail is evident in the packaging process, which uses recyclable materials and protective systems to safeguard the product during transport.

Made-to-design profiles (L-U-C-A) offer a tangible response to the rising demand for bespoke components, combining technical precision, reliability, and environmental responsibility. A further demonstration of SIPI’s ability to innovate while staying true to its artisanal roots.