Sawn stainless steel flats: precision and versatility by SIPI

In industrial applications where precision is not a preference but a strict requirement, sawn stainless steel flats represent a technically sound solution. Since 1992, SIPI has established itself as a trusted manufacturer of flat bars and custom-formed profiles, offering a range of sawn flats engineered to deliver dimensional accuracy and mechanical reliability—even in the most complex scenarios.

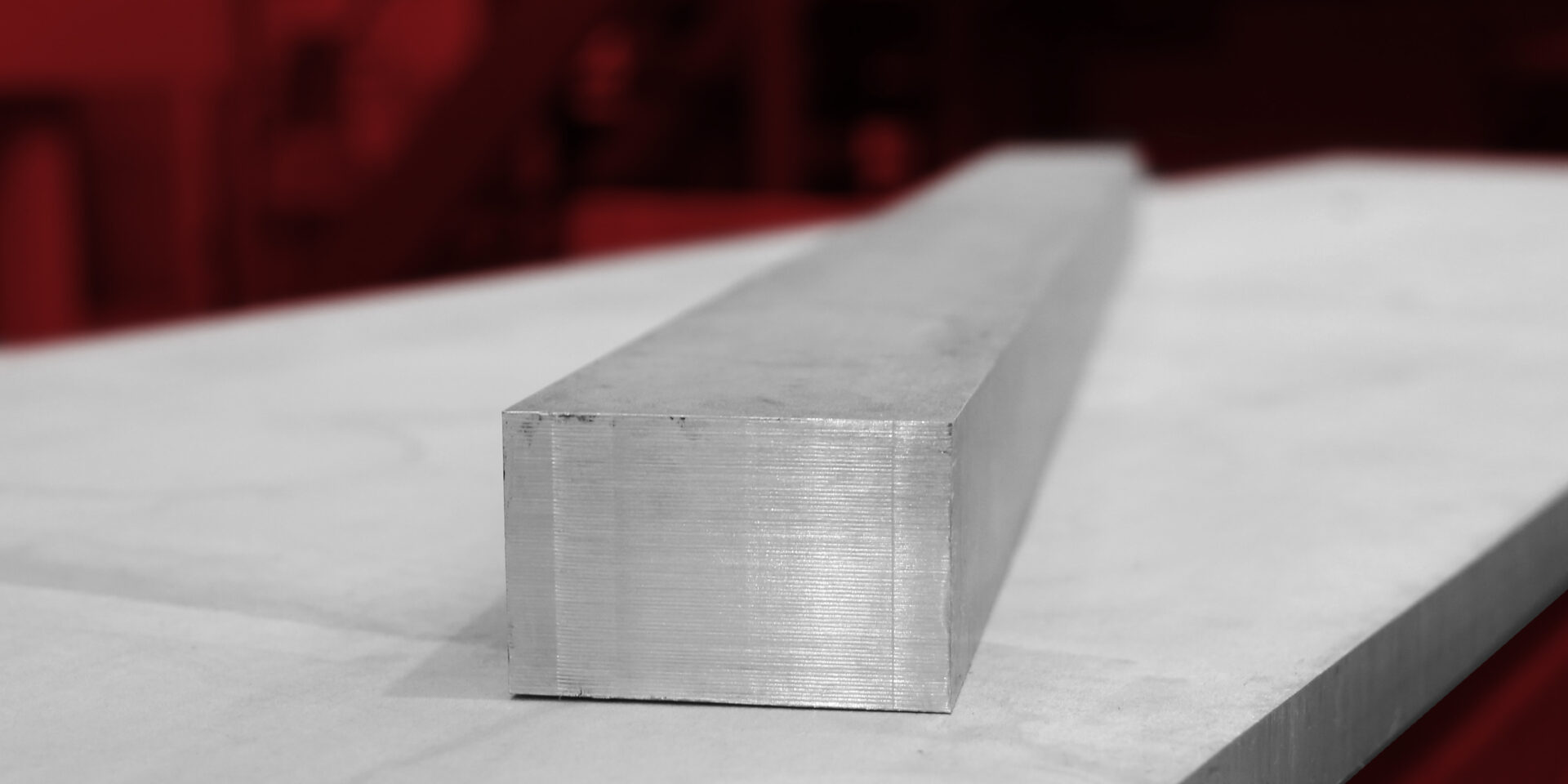

These flat bars feature sharp 90° edges and retain the characteristic marks of the saw blade—technical details that underscore the origin and accuracy of the cutting process. Dimensions range from a minimum of 30×15 mm to a maximum of 500×100 mm, with lengths from 4,000 to 6,000 mm. This makes them ideal for processes requiring geometric precision and mechanical consistency, such as edge-on rolling, even with substantial thicknesses (15 and 20 mm).

In keeping with SIPI’s production philosophy, each flat bar undergoes thorough inspections throughout the manufacturing cycle, ensuring full compliance with the required specifications. The company’s flexible production system also allows for bespoke solutions and small-batch orders.

Packaging is designed with both product protection and environmental sustainability in mind, using galvanised strapping, wooden supports, and recyclable polyethylene film—available upon request.

Combining artisanal expertise with advanced industrial technology, SIPI delivers products that meet the highest international standards—already chosen by clients in over 40 countries. The sawn flats exemplify how precision can make a real difference—not only in performance, but also in the longevity and safety of the final application.