The SIPI product range: quality, flexibility and full control across the entire supply chain

Since 1992, SIPI has specialised in the production of stainless steel flat bars and custom-bent profiles, combining industrial efficiency with the meticulous care of traditional craftsmanship. The company’s mission has always been clear: to grow through uncompromising product quality and service excellence, while adapting to a global market that evolves continuously. Today, SIPI supplies customers in more than 40 countries worldwide, maintaining stringent standards at every stage of production.

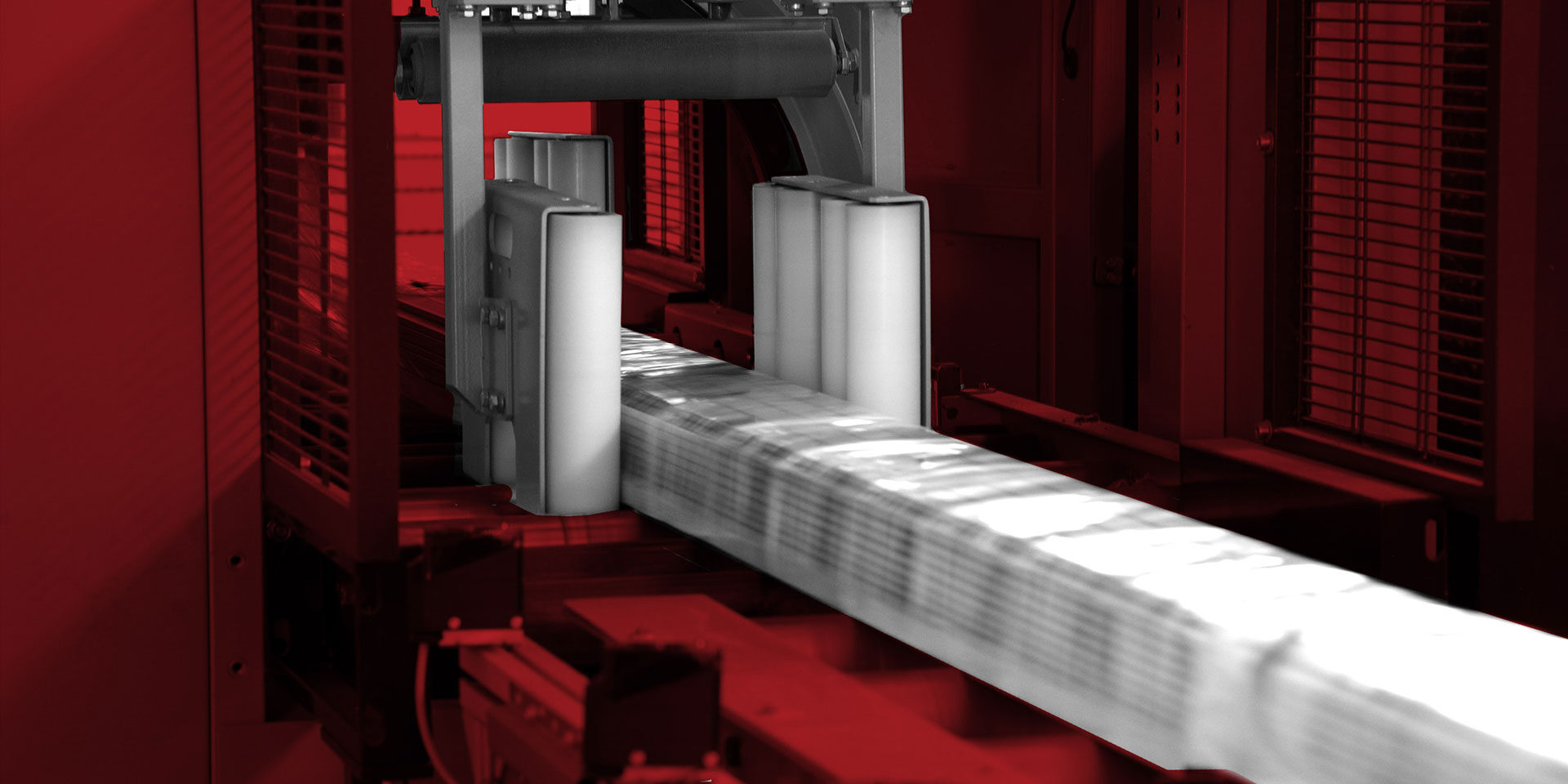

The flat bars are produced through sheet-metal shearing followed by precision profiling, a process designed to deliver consistent geometry and a flawless finish. Workability is a defining element of SIPI’s offering: each bar is engineered to perform reliably across a wide range of industrial applications, from simple fabrication to demanding forming and bending operations. Their corrosion resistance, mechanical strength and clean appearance make them suitable for long-life, low-maintenance environments. All products come with EN 10204/3.1 certification, meeting European and international requirements.

A comprehensive and versatile range

SIPI’s product portfolio includes solutions designed to meet specific technical and dimensional needs:

- Sheared and deburred flat bars – the most widely used version of stainless steel flat bars, ideal for bending and calendering;

- Sheared, non-deburred flat bars – delivered with sharp edges, suitable for applications where raw edges pose no functional limitation;

- Saw-cut flat bars – produced from plate, providing consistent dimensional accuracy for applications requiring tight tolerances;

- Made-to-design profiles (L, U, C, A) – flat bars bent to project specifications to create bespoke stainless steel profiles.

These products are manufactured using two shearing lines, three profiling machines and a band saw, enabling production in sizes ranging from 10×3 mm to 500×100 mm and lengths between 3 and 6 metres, including small-batch orders.

Precision through a craft-inspired process

Each bar undergoes individual inspection by SIPI’s skilled operators. This approach, where advanced machinery is integrated with hands-on quality control, ensures that the mechanical properties of the stainless steel are preserved and that every product offers high workability. This includes demanding processes such as edge-up calendering, even on thicknesses of 15 and 20 mm.

The company’s production flexibility also allows SIPI to supply small batches in special grades such as 316Ti, 321, 309S, 310S and ferritic steels, a capability that strengthens SIPI’s competitiveness in specialised and time-sensitive markets.

Steel grades available

SIPI processes an extensive range of stainless steel grades, including:

- AISI 304L – EN 1.4307

- AISI 321 – EN 1.4541

- AISI 316L – EN 1.4404

- AISI 316Ti – EN 1.4571

- AISI 430 – EN 1.4016

- Duplex – EN 1.4462

- AISI 309S – EN 1.4833

- AISI 310S – EN 1.4845

- AISI 904L – EN 1.4539

Packaging designed for integrity and protection

Every bundle is secured with galvanised steel strapping, wooden supports and—on request—a thin recyclable polyethylene film. This attention to packaging reflects SIPI’s broader commitment to product integrity and environmental care.

Choosing SIPI means partnering with a company capable of delivering reliable, precise and flexible stainless steel solutions, shaped by decades of experience and a strong commitment to quality.